Iseli yelanga iyithuluzi eliguqula ngokuqondile amandla okukhanya abe amandla kagesi ngokusebenzisa umphumela wesithombe sikagesi noma umphumela we-photochemical.Amaseli elanga anefilimu emincane esebenza ngomphumela wesithombe kagesi yiwo ajwayelekile, futhi indlela yokukhetha amaseli elanga iyabakhathaza abanye abantu.Namuhla, ngizokwethula kafushane ulwazi mayelana nokuthengwa kwamaseli elanga.Ngethemba ukuthi iyakusiza.

Njengamanje, amaseli elanga emakethe ahlukaniswe abe i-amorphous silicon ne-crystalline silicon.Phakathi kwazo, i-crystalline silicon ingahlukaniswa ibe yi-polycrystalline silicon kanye ne-silicon eyodwa ye-crystal.Ukusebenza kahle kokuguqulwa kwe-photoelectric kwezinto ezintathu yilezi: i-silicon ye-monocrystalline (kufika ku-17%) > i-polycrystalline silicon (12-15%) > i-amorphous silicon (cishe i-5%).Kodwa-ke, i-crystalline silicon (i-crystal silicon eyodwa ne-polycrystalline silicon) empeleni ayikhiqizi ukukhanya okubuthakathaka, futhi i-silicon e-amorphous inhle ekukhanyeni okubuthakathaka (amandla ekuqaleni mancane kakhulu ngaphansi kokukhanya okubuthakathaka).Ngakho-ke, sekukonke, i-silicon ye-monocrystalline noma i-polycrystalline silicon ye-solar cell materials kufanele isetshenziswe.

Lapho sithenga amangqamuzana elanga, ukugxila kokunaka kungamandla esitokisi selanga.Ngokuvamile, amandla ephaneli yelanga alingana nendawo ye-wafer yelanga.Indawo ye-wafer ye-solar cell ayilingani ncamashi nendawo yephaneli ye-solar encapsulation, ngoba nakuba amanye ama-solar panel makhulu, i-wafer eyodwa yelanga ihlelwe ngegebe elibanzi, ngakho-ke amandla ephaneli enjalo yelanga akudingekile. phezulu.

Ngokuvamile, ukuphakama kwamandla ephaneli yelanga, kungcono, ukuze i-current ekhiqizwa elangeni ibe nkulu, futhi ibhethri layo elakhelwe ngaphakathi lingashajwa ngokugcwele ngokushesha.Kodwa empeleni, kudingeka kube nokulinganisela phakathi kwamandla ephaneli yelanga kanye nokuphatheka kweshaja yelanga.Ngokuvamile kukholakala ukuthi amandla amancane weshaja yelanga awakwazi ukuba ngaphansi kuka-0.75w, futhi iphaneli yelanga yamandla wesibili ingakwazi ukukhiqiza i-current ye-140mA ngaphansi kokukhanya okuqinile okujwayelekile.Okwamanje okukhiqizwa ekukhanyeni kwelanga okuvamile cishe ku-100mA.Uma i-chargency yokushaja incane kakhulu ngaphansi kwamandla esibili, ngeke kube khona umphumela osobala.

Ngokusetshenziswa okubanzi kwemikhiqizo ehlukahlukene yelanga, amaseli elanga asetshenziswa kabanzi empilweni yethu.Kodwa lapho sibhekene nazo zonke izinhlobo zamaseli elanga emakethe, kufanele sikhethe kanjani?

1. Ukukhethwa umthamo webhethri cell cell

Njengoba amandla okokufaka wesistimu yokuphehla amandla elanga ye-photovoltaic engazinzile ngokwedlulele, ngokuvamile kuyadingeka ukulungisa uhlelo lwebhethri ukuze lusebenze, futhi izibani zelanga azifani, futhi ibhethri kufanele lilungiselelwe ukusebenza.Ngokuvamile, kukhona amabhethri e-lead-acid, amabhethri e-Ni-Cd, namabhethri e-Ni-H.Ukukhethwa kwabo kwamandla kuthinta ngokuqondile ukuthembeka kwesistimu kanye nentengo yesistimu.Ukukhethwa komthamo webhethri ngokuvamile kulandela lezi zimiso ezilandelayo: okokuqala, ngesisekelo sokuthi ingahlangabezana nokukhanya kwasebusuku, amandla ezingxenye zamaseli elanga phakathi nosuku kufanele agcinwe ngangokunokwenzeka, futhi ngesikhathi esifanayo, kufanele ukwazi ukugcina amandla kagesi ahlangabezana nezidingo zokukhanya eziqhubekayo zamafu nezimvula ebusuku.Umthamo webhethri mncane kakhulu ukuthi ungahlangabezana nezidingo zokukhanyisa ebusuku, futhi umthamo webhethri mkhulu kakhulu.

2. Ukukhethwa kwefomu le-solar cell packaging

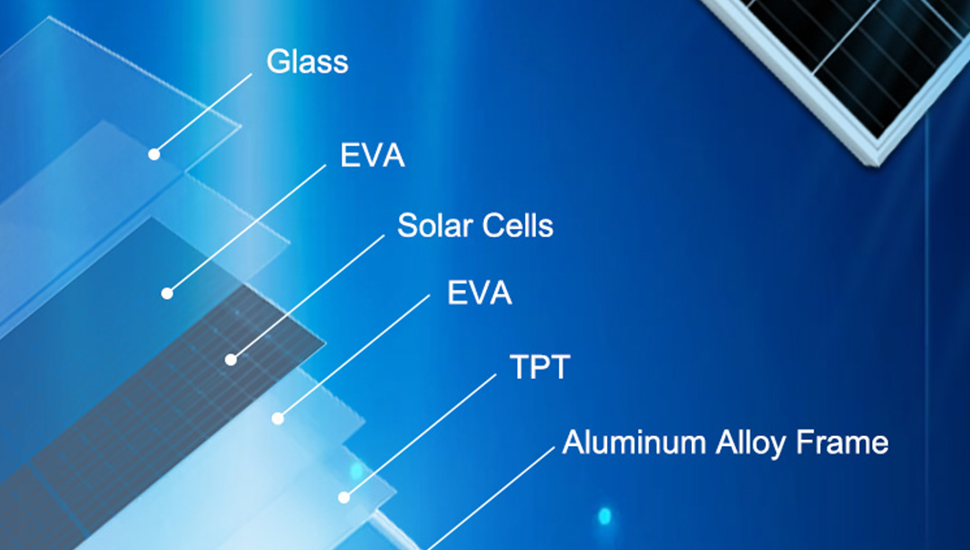

Njengamanje, kunezinhlobo ezimbili eziyinhloko zokupakisha zamaseli elanga, i-lamination neglue.Inqubo ye-lamination ingaqinisekisa impilo yokusebenza yamaseli elanga iminyaka engaphezu kwengu-25.Nakuba i-glue-bonding yayiyinhle ngaleso sikhathi, impilo yokusebenza yamaseli elanga yiminyaka eyi-1 ~ 2 kuphela.Ngakho-ke, ukukhanya kotshani belanga obunamandla aphansi ngaphansi kuka-1W kungasebenzisa ifomu lokupakisha le-glue-drop uma ingekho iminyaka yokuphila ephezulu.Ngesibani selanga esinempilo yesevisi ecacisiwe, kunconywa ukusebenzisa ifomu lokupakisha laminated.Ngaphezu kwalokho, kukhona ijeli ye-silicone esetshenziselwa ukufaka amangqamuzana elanga ngeglue, futhi kuthiwa impilo yokusebenza ingafinyelela iminyaka eyi-10.

3. Ukukhethwa kwamandla elanga lamaseli

Amandla okukhipha amaseli elanga i-Wp esiwabiza ngokuthi amandla okukhipha iseli yelanga ngaphansi kwezimo zokukhanya kwelanga ezijwayelekile, okungukuthi: izinga elingu-101 elichazwe yi-European Commission, amandla emisebe ngu-1000W/m2, ikhwalithi yomoya ngu-AM1.5, kanye izinga lokushisa lebhethri ngu-25°C.Lesi simo sicishe sifane neselanga emini emini libalele.(Ezindaweni eziphansi zoMfula iYangtze, ungasondela kuphela kuleli nani.) Lokhu akunjengoba abanye abantu babecabanga.Uma nje kunokukhanya kwelanga, kuzoba namandla okukhiphayo alinganiselwe.Ingasetshenziswa futhi ngokujwayelekile ngaphansi kwezibani ze-fluorescent ebusuku.Okusho ukuthi, amandla okukhipha iseli yelanga awahleliwe.Ngezikhathi ezahlukene kanye nezindawo ezahlukene, amandla okukhipha iseli elifanayo lelanga ahlukile.Idatha yokukhanya kwelanga, phakathi kobuhle nokonga amandla, iningi labo likhetha ukonga amandla.

Isikhathi sokuthumela: Jul-08-2022